DTF Heat Transfer Film is one of the most important supplier in Direct to Film printing process, T-shirt printing cannot be done without transferring the print patterns onto the clothes, (so the DTF Film is called DTF Transfer Film as well), Hot Peel Film and Cold Peel Film are 2 types of DTF Film used for the transferring.

The key differences between Hot Peel Film and Cold Peel Film are: Hot Peel Film is more efficient, for large patterns with lower press temperature (140℃-150℃) while Cold Peel Film can be applied to more types of fabrics with longer-term water washing fastness at lower cost.

Key Differences Between Hot Peel Film and Cold Peel Film

The following table presents major differences between the 2 types of films from: main component, pressing temperature, pressing time, application material, transfer size, cost, efficiency and washing fastness.

What is DTF Film?

| Hot Peel Film | Cold Peel Film | |

| Main Component | Wax | Silicon |

| Pressing Temperature & Processing Time | Pressing at 140-150℃, 5-10 seconds; Cooling 2-3 seconds | Pressing at 150-170℃, 10-20 seconds; Cooling 30 seconds |

| Application Material | All kinds of fabrics | All kinds of fabrics, Perfect for special fabrics such as: tarpaulin, coated cloth, canvas, flannelette |

| Transfer Features | Large images, patterns, such as: T shirt print on front and back | Complex, intricate patterns such as fine lines, small icons, letters with details |

| Cost | More expensive | Less expensive |

| Efficiency | More efficient, up to 100 T-shirt in a hour | Less efficient |

| Washing Fastness | Shorter-term than Cold Peel Film | Long-term water washing fastness |

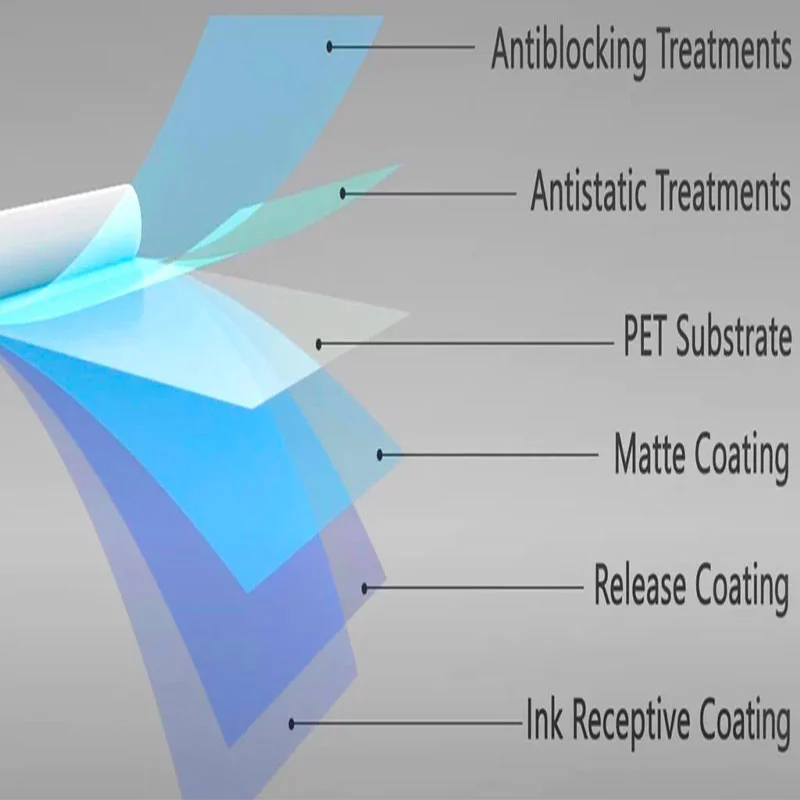

DTF Film (DTF PET Film, DTF Transfer Film) is a special film with coating, it’s required in DTF (direct to film) printing that transfers design to fabrics or other materials. Usually, there are 6 layers contained: base layer, release layer, viscose layer, printing layer, protective layer, and antistatic layer.

To adapt different DTF printing requirements and printout best quality, usually, there are 2 versions of DTF film offered: hot peel film and cold peel film. (How To Use DTF Film?)

Detail Differences Between Hot Peel and Cold Peel DTF Film

Main Component of DTF Film: Hot Peel vs. Cold Peel

In order to ensure a better release effect, the main component of hot peel film is wax, which is difficult to melt and apply evenly. So the requirements for the coating process are more strict.

The main component of the cold film is silicon. Silicon is easier to melt and apply to film compared with hot peel film. That’s why cold film is more stable than hot peel film in the market.

Hot Peel Film vs. Cold Peel Film: Different Pressing Temperature and Processing Time

Hot peel film needs to be pressed under the temperature of 140-150℃ for 5-10 seconds with 2-3 seconds cooling time after pressing.

The pressing temperature of cold peel film is longer than that of hot peel film, usually at 150-170℃ for 10-20 seconds, after pressing, it requires about 30 seconds of cooling time before tearing off.

Hot Peel Film vs. Cold Peel Film: Application Materials, Transfer Features

Both hot peel film and cold peel film are suitable for all kinds of fabrics, however, cold peel film is perfectly suitable for some special fabrics such as tarpaulin and coated cloth, it also can be applied to rough texture fabric such as canvas and flannelette. These fabrics have enough time to restore adhesion and flatness after heat pressing.

If using hot peel film onto the above materials, it is easy to create wrinkles and perhaps damage the fabric, the final print result is less quality than cold peel film.

As a result, cold peel film is ideal for printing and requires better quality for complex patterns, small letters and icons, intricate lines, and transferring texture.

Cost of Hot Peel Film and Cold Peel Film, Which is Higher?

As producing process of hot peel film is more complicated and requirements for uniformity and coating accuracy of the coating machine are stricter, hence, cost of hot peel film is higher than cold peel film.

The efficiency of Hot Peel Film and Cold Peel Film

As introduced in the above section, hot peel film can be torn off nearly without waiting after pressing, this saves a lot of time. The printing business owner or operator just needs to focus on the heat press, once the heat press is finished, you can tear off the film and then quickly produce another piece of t-shirt. This makes 100 pieces of t-shirt printing in one hour possible.

On the other hand, as cold peel film has better printing quality on detail and granularity, the efficiency is relatively lower than hot peel film.

Different Washing Fastness Between Hot Peel and Cold Peel Film

Hot peel film has an adhesive layer that uses a water-based back-coating technique. If the adhesive layer is not torn off in time, the cooled glue will stick to the clothing, making it difficult to remove the film from the clothing. Furthermore, there is no guarantee of the long-term water-washing fastness of the water-based adhesive layer.

The adhesive layer of cold peel film uses an oil-based back-coating method, which has good washing fastness.

Hot Peel vs. Cold Peel Film, Which is Really Better?

All in all, hot peel film and cold peel film have their own transfer features suitable for different printing requirements.

In general printing business scenario, choosing DTF hot peel film is ideal for large volume printing onto common fabrics such as cotton T-shirts, the cold peel film is a better choice on print complex and fine small patterns onto special material such as tarpaulin, coated cloth, canvas, and flannelette.

Though choosing DTF transfer film is not as complicated as choosing the best DTF printer for a profitable printing business, here are 6 key features that could help you to choose the right DTF film:

- Ink-absorption capacity

- Coating layer

- Powder shaking effect

- Release effect

- Storage capacity

- High-temperature resistance

Choosing the most suitable DTF film is a key influencer to high-performance DTF printing for the successful printing business, no text nor technology is better than trying it yourself, you can request DTF film sample (free) to feel the difference between hot peel DTF film and cold peel film and decide the better one.